© 2018 CMEC AQUA Valve Manufacturing Co.,LTD. All rights reserved. Site Map Link Designed by iwonder.cn

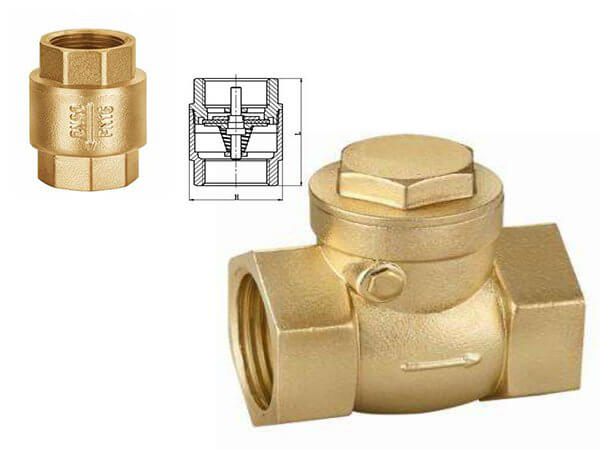

Today, we will introduce the check valve to you. Most people know little about check valve types and the maintenance of single check valve. We hope this article can help you to know more about check valve.

The function of the noise check valve is to prevent the reverse direction flow and only allow the medium to flow in one direction. Normally non return valve is operated automatically, and the disc opens under a fluid pressure that flows in one direction. When the flow is in the opposite direction, the flow is cut off by the flow pressure and the self-aligning disc of the disc to the seat. Suitable for medium containing solid particles and viscosity.

Silencing check valve belong to automatic valve class, its role is to prevent the backflow medium pipeline, it is mainly used for medium on the one-way flow of pipeline, only allowed to medium flows in one direction, in order to prevent accidents.

Take the international representative of the sound check valve brand American VTON as an example, here is an introduction to the maintenance and maintenance of the noise check valve!

1) the opening and closing parts should be in the closing device while storage, and the following work should be done:

The valve flap should be fixed to the open position.

In the end of the two ends of the path, the inner mouth is blocked with foam board, and the port shall be closed with a stuffy lid to prevent dust and rust, and keep the channel clean and the end face smooth.

Proper packing protection, shockproof and anti-collision in the cylinder parts;

2) when the noise check valve is placed, it should be stable, and the pneumatic driving device should be up, and it shall not be crowded with each other.

3) regular inspection should be carried out for long time placement. Every three months to the two channels, seal surface dirt and rust, the welding mouth of the protection of the inspection, wiping dirt and rust, repainting anti-rust oil to protect.

4) check valves shall be installed on equipment, devices and pipelines to prevent the flow of media from going upstream.

5) the noise check valve is generally applicable to clean media, which should not be used for medium containing solid particles and high viscosity;

6) the vertical noise check valve should be used in the horizontal pipe with a nominal total of 50mm.

7) the noise check valve shall be stored in a dry and ventilated room to prevent moisture, rain and rust.